Is Zirconia a Ceramic? The Power of Advanced Engineering Materials

Problem: Are you confused about whether zirconia is a ceramic? Many industries face costly mistakes when choosing the wrong materials. Dental clinics waste thousands on failed implants. Manufacturing companies lose millions on parts that break too soon. And engineers struggle…

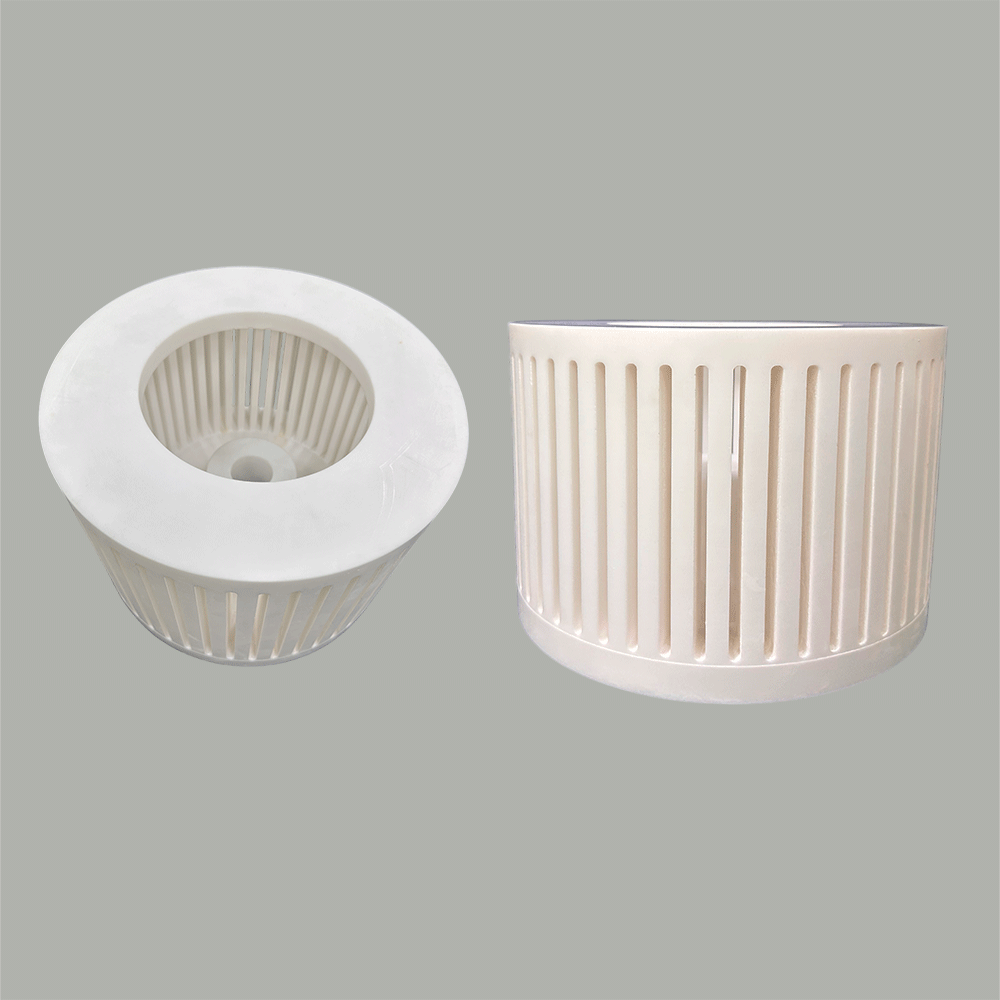

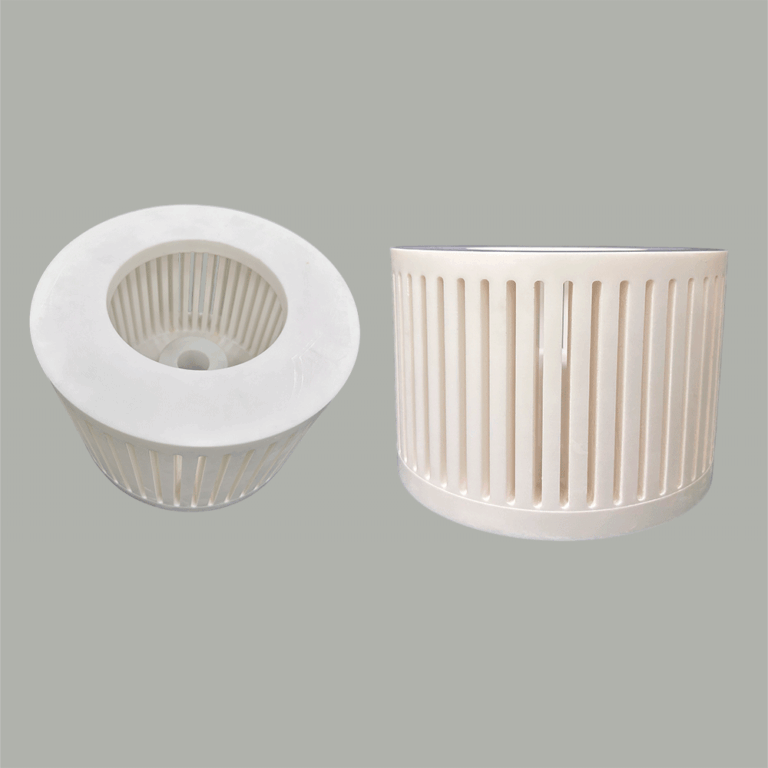

Custom partially stabilized zirconia 3y tzp zirconia parts

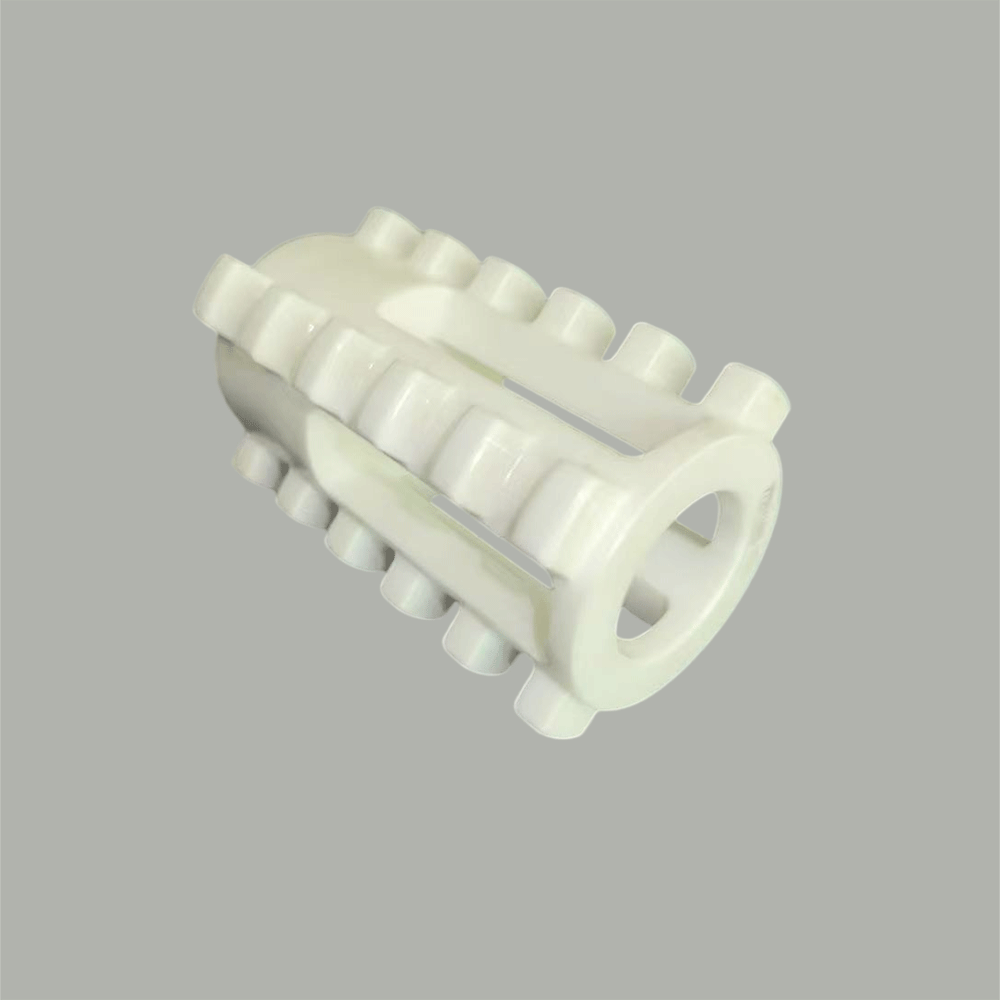

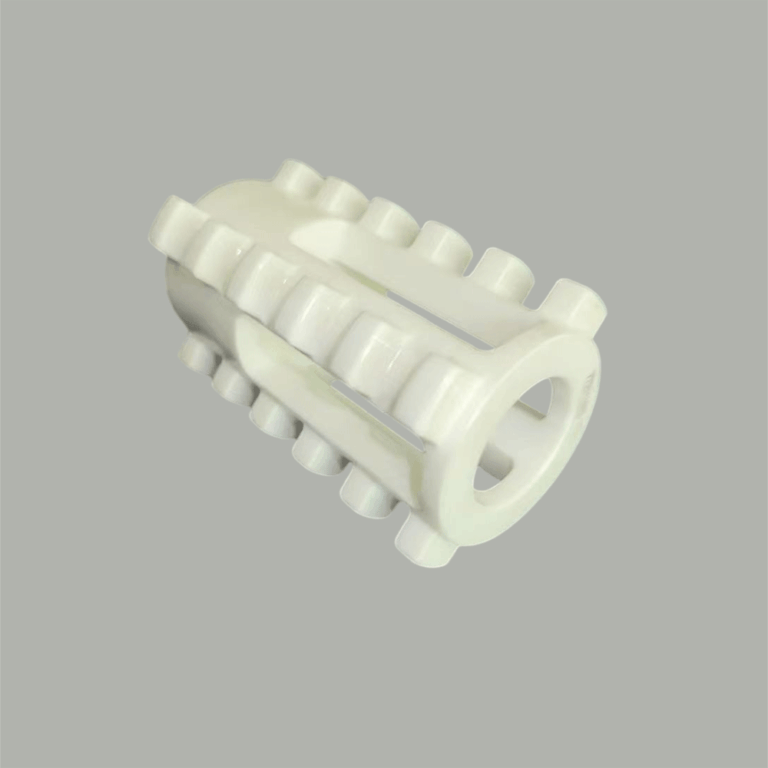

ceria stabilized zirconia dioxide zirconium dioxide ceramic

zro2 ceramic yttria stabilized zirconia ceramic

Polished partially stabilized sintered zirconia ceramic parts

High Polishing zirconia ceramic balls

Shiny White Balls! Look at these balls!They are white and shiny.They are very round.They are made from special stuff. What Are These Balls? These balls are called zirconia ceramic balls.It is a long name! You can call them hard white…