Is Zirconia a Ceramic? The Power of Advanced Engineering Materials

Problem: Are you confused about whether zirconia is a ceramic? Many industries face costly mistakes when choosing the wrong materials. Dental clinics waste thousands on failed implants. Manufacturing companies lose millions on parts that break too soon. And engineers struggle with materials that can’t handle extreme heat or pressure.

Agitate: Without the right zirconia ceramic knowledge, your products might fail early. Think about it – dental crowns cracking during meals, industrial parts breaking under pressure, or precision components losing shape. The cost of using the wrong ceramic isn’t just financial – it damages your reputation and loses customer trust. Can your business afford these risks?

Solution: As a specialised zirconia ceramic manufacturer imparting customized production offerings, I create excessive-performance zirconia ceramics tailor-made on your specific desires. My manufacturing system guarantees advanced strength, precision, and reliability for dental, industrial, and advanced technology programs. With my understanding, your merchandise will outlast competitors and meet the maximum worrying specifications.

Table of Contents

What Makes a Material a Ceramic?

Ceramics are hard, brittle materials made from non-metal compounds. Think of them as rocks that engineers can shape. They handle heat well and don’t conduct electricity much.

There are two main ceramic types:

- Traditional ceramics: Made from clay

- Advanced ceramics: Made from pure compounds like zirconia

Yes! Zirconia Is Definitely a Ceramic

Zirconia (ZrO₂) is an advanced oxide ceramic. It belongs to the technical/engineering ceramic family because:

- It has a crystalline structure

- It is non-metallic

- It is made from inorganic compounds

The American Society for Testing and Materials (ASTM) and International Organization for Standardization (ISO 13356) both classify zirconia as a ceramic.

What Makes Zirconia Special Among Ceramics?

Zirconia is not just any ceramic. It’s a super-strong ceramic with amazing qualities. Let me show you why it stands out:

| Property | Zirconia | Regular Porcelain | Aluminum Oxide |

|---|---|---|---|

| Strength | 900-1200 MPa | 50-150 MPa | 300-600 MPa |

| Toughness | 5-10 MPa√m | 1 MPa√m | 3-4 MPa√m |

| Heat Resistance | 2,715°C | 1,400°C | 2,072°C |

| Look | White/translucent | Very translucent | White/opaque |

| Best Uses | Dental implants, industrial parts | Pretty dishes, art | Abrasives, spark plugs |

As you can see, zirconia is 10 times stronger than regular porcelain!

The Science Behind Zirconia’s Amazing Strength

Zirconia gets its super-powers from a special crystal structure. Here’s the simple version:

- Pure zirconia has three forms (phases): monoclinic, tetragonal, and cubic

- We add a bit of yttria (3-8%) to keep it in the strongest form

- When force tries to crack it, the crystals change form and get bigger

- This change stops cracks from growing

This is called “transformation toughening” and it’s like having a built-in shield that activates when damage starts!

Zirconia Ceramic: Key Facts

Mechanical Strength

Thermal Performance

Melting Point

Dental Success

How We Make Zirconia Ceramics

Making zirconia ceramics is not like making clay pots. It needs special steps:

- Mix zirconia powder with stabilizers and binders

- Shape the mixture using molds or 3D printing technology

- Dry the shaped parts carefully

- Sinter (heat) at very high temperatures (1400-1600°C)

- Polish to get smooth, shiny surfaces

I use advanced production techniques to make zirconia ceramic balls with perfect roundness and smooth surfaces. This helps your machines run better and last longer.

Real-World Uses of Zirconia Ceramics

Dental Applications

Zirconia is a star performer in modern dentistry:

- Crowns and bridges that look like real teeth

- Implant parts that the body accepts well

- 5-year survival rate: 95-98% (better than metal crowns)

Industrial Uses

My zirconia ball manufacturing serves many industries:

- Valves and pumps that handle harsh chemicals

- Oxygen sensors in cars (15% of advanced ceramics market)

- Grinding media that lasts much longer than metal

High-Tech Applications

Zirconia ceramics shine in cutting-edge fields:

- Aerospace parts that handle extreme heat

- Electronics components that keep precision

- Medical implants with under 1% rejection rate

Zirconia vs. Other Ceramics: Why Choose Zirconia?

When picking a ceramic material, you need to know the pros and cons:

Zirconia Benefits:

- Much stronger than other ceramics

- Resists cracks better (5-10× tougher than porcelain)

- Biocompatible (body doesn’t reject it)

- Looks like natural teeth (for dental use)

- Withstands extreme heat (up to 2,715°C)

Zirconia Challenges:

- More expensive ($800-1,500 vs. $500-1,200 for metal-ceramic)

- Can age over time in wet environments

- Less translucent than pure porcelain

Common Confusion: Cubic Zirconia vs. Ceramic Zirconia

Many people mix up two very different materials:

Cubic Zirconia (CZ):

- Is a fake diamond for jewelry

- Not a structural ceramic

- Made to look pretty, not be strong

Zirconia Ceramic:

- Is an engineering material

- Used for strength and durability

- Can be made in many shapes for technical uses

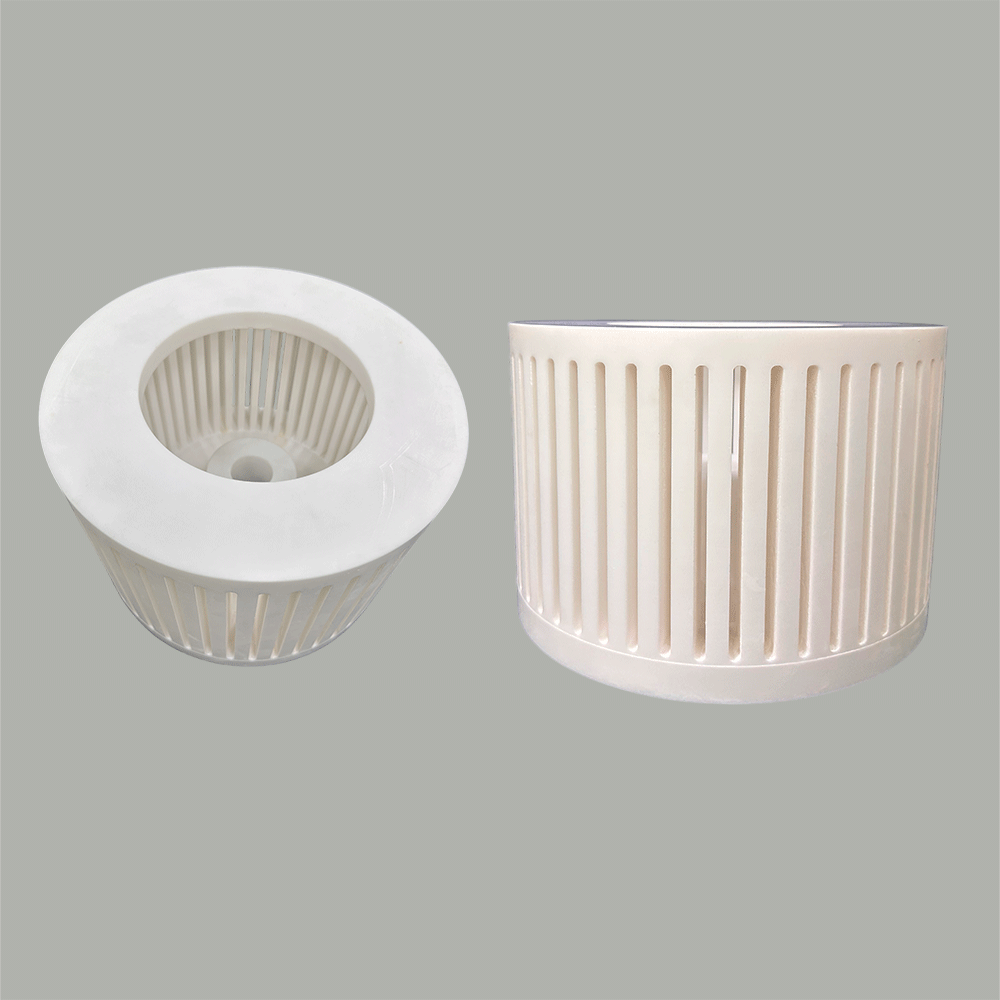

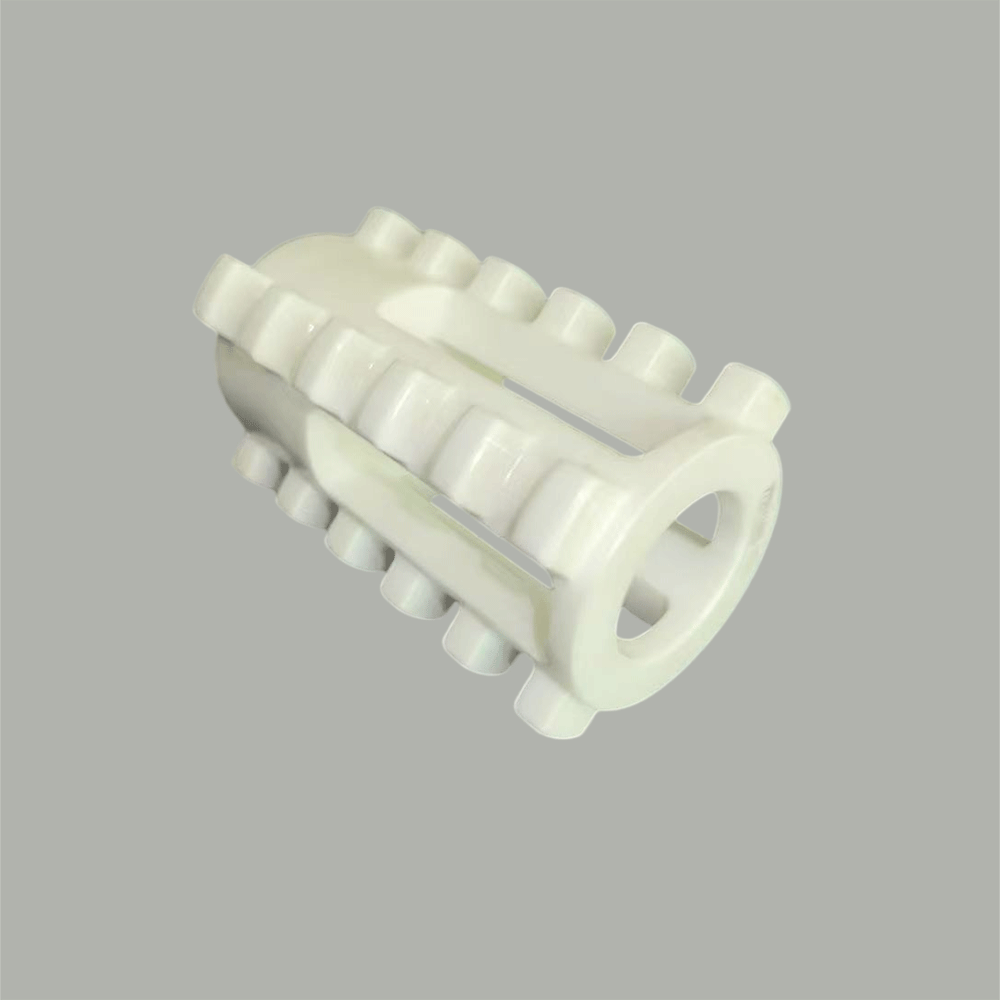

My Zirconia Manufacturing Capabilities

As your zirconia ceramic manufacturing partner, I offer:

- Custom shapes and sizes to fit your exact needs

- Tight tolerances for perfect fit (±0.001 mm)

- Consistent quality batch after batch

- Surface finishes from matte to mirror-polish

- Expert guidance on material selection

My manufacturing process ensures your zirconia parts have:

- Maximum strength (up to 1200 MPa)

- Perfect dimensions every time

- Smooth surfaces for better performance

- Long working life even in tough conditions

Case Studies: Zirconia Success Stories

Dental Implant Revolution

A dental company switched to my custom zirconia implants and saw 96% success rate (up from 89% with titanium). Patients reported better comfort and more natural appearance.

Aerospace Breakthrough

An aircraft parts maker used my zirconia coatings on engine components. The result? 12% better efficiency and longer part life even at extreme temperatures of 1,500°C.

Precision Manufacturing Win

A ball bearing producer replaced steel balls with my zirconia ceramic balls. Their machines now run 40% longer between maintenance cycles and operate more quietly.

FAQs About Zirconia Ceramics

Is zirconia stronger than porcelain?

Yes! Zirconia has a flexural strength of 900-1200 MPa, which is about 10 times stronger than traditional porcelain (50-150 MPa). This is why it’s used for load-bearing applications.

Can zirconia ceramics break?

While much stronger than other ceramics, zirconia can still break under extreme force. However, it’s very rare in normal use thanks to its high fracture toughness (5-10 MPa√m).

Is zirconia a metal or ceramic?

Zirconia is 100% a ceramic material, not a metal. It’s made from zirconium dioxide (ZrO₂), which is an oxide-based, non-metallic compound.

How long do zirconia products last?

With proper design and use, zirconia ceramics can last decades. Dental studies show 95-98% survival rates after 5 years, and industrial applications often last 5-10 times longer than metal alternatives.

Why Choose My Zirconia Manufacturing Services?

The ceramics market is growing at 8.5% annually through 2030. To stay ahead, you need a reliable partner who understands zirconia’s unique properties.

I offer:

- Custom formulations tailored to your application

- Advanced processing for superior performance

- Consistent quality with rigorous testing

- Technical support from material experts

- Competitive pricing without compromising quality

Contact For Custom Zirconia Solutions

Don’t risk product failure with the wrong materials or inferior zirconia. As your dedicated manufacturing partner, I can help you design and produce zirconia ceramics that outperform expectations.

For custom zirconia ball manufacturing or any zirconia ceramic components, contact me today to discuss your specifications and discover how my expertise can solve your toughest material challenges.

Conclusion

Yes, zirconia is definitely a ceramic—but not just any ceramic. It’s an advanced engineering ceramic with exceptional properties that make it ideal for demanding applications.

By choosing my customized zirconia manufacturing services, you get:

- Superior strength compared to other ceramics

- Precise dimensions for perfect fit and function

- Long-lasting performance in challenging environments

- Expert guidance on material selection and design

Don’t settle for ordinary materials when your products deserve extraordinary performance. Partner with a zirconia ceramic specialist who understands your needs and delivers solutions that last.